Sunday 15 January 2012

Awesomatix A700 - electronics installation

Labels:

24k gold,

90C,

A700,

Awesomatix,

EFRA,

electric,

EP TOURING,

IFMAR,

inovation,

ISTC,

JMRCA,

LIPO,

quality,

r/c car,

R10PRO,

rc cars,

russian,

TEAM ORION,

touring car,

tuned

Friday 13 January 2012

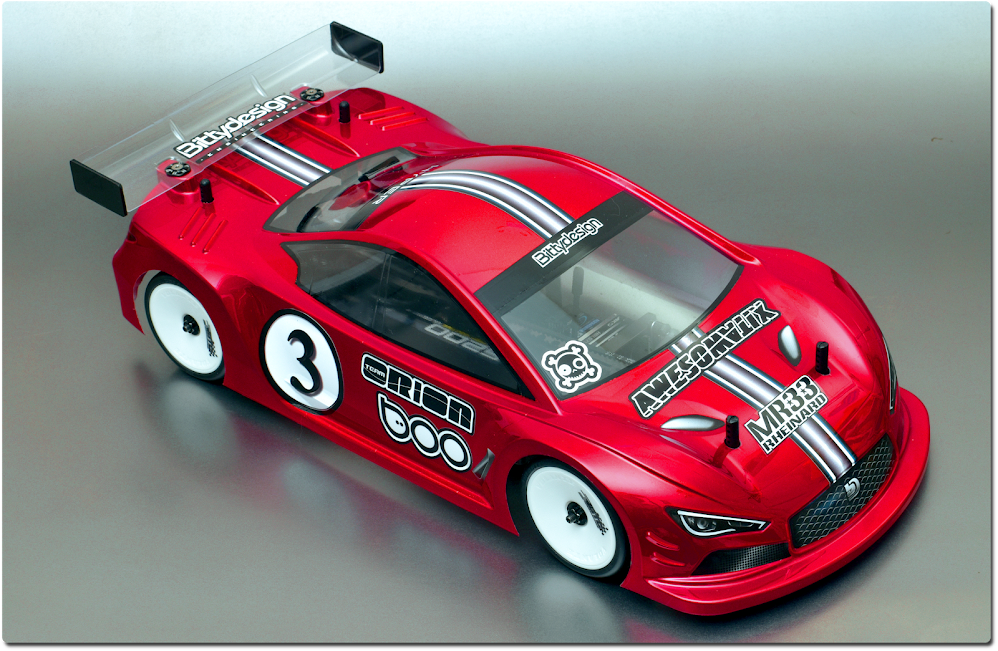

Awesomatix A700 Presentation

The AWESOMATIX A700

I had the opportunity through the kind gesture of the designer and overall creator of this car , Mr. Oleg Babich, to receive a kit and make a photo presentation.

Through the positive feedback of the current owners and some impressive results by privateer racers at big events such as the famous European Touring car Series, I was aware that Οleg was on to something good and the kit should be impressive.

Nothing had prepared me for what I experienced during the assembly of this kit.

Viewing Tip: Some photos are much larger in size so you can enjoy in HD. Right click and open in a new tab or new window.

1. Front and rear wheel hubs

I had the opportunity through the kind gesture of the designer and overall creator of this car , Mr. Oleg Babich, to receive a kit and make a photo presentation.

Through the positive feedback of the current owners and some impressive results by privateer racers at big events such as the famous European Touring car Series, I was aware that Οleg was on to something good and the kit should be impressive.

Nothing had prepared me for what I experienced during the assembly of this kit.

Viewing Tip: Some photos are much larger in size so you can enjoy in HD. Right click and open in a new tab or new window.

1. Front and rear wheel hubs

The housing is made of aluminum. The finish is great and the

fit is spot on. I am very impressed by the choice of anodized color on all

aluminum parts, and Oleg's attention to detail went as far as providing some

beautiful high quality dark shiny black fasteners.

2. Axles

In front is a double joint axle and at the rear a more

standard axle. By standard I am referring to the concept because the actual

design is again unique, getting rid of any set screws which may come off during

racing and also 'bind' the action of the axle. The design consists of some

extremely small parts, all with the goal to minimize rotating mass. The risk

when making such small parts is the dimensional tolerances. They have to be

absolutely perfect and this is exactly how they are, perfect! Once assembled

the front axles with the double joint have the smoothest action I've ever seen.

The rear axles are a bit tight, but this will later disappear once installed on

the aluminum wheel hubs and are tightened against the wheel.

3. Suspension Arms.

These are made of carbon fiber sheet, they are thick and

look quite robust, so they should survive most type of crashes. The wheel hubs

with the axles fit on the arms with a smart way so as to be able for the user

to adjust the pressure on the ball end, thus achieving the least possible

friction with no slop.

In the past I 've had some bad experience with cars that

secured their suspension arms with ball joints and not shafts. The reason is

that if the tolerances are not perfect then in most cases the suspension would

bind and in order to fix that you'd need to enlarge the hole were the ball end

nests, and this will require a lot of handwork and in the end some slop will be

visible. The A700’s suspension arms manage to achieve perfectly free movement

without any slop and that is possible because of the tight tolerances (how

many times am I going to say this word in this report?) and because of

the smart, two piece system where between the Pivot ball and the suspension arm

there is low friction ball cup which eliminates any gaps between the arm and

the pivot ball while providing frictionless movement.

5. Now a short demonstration of the quality, fit and finish of

the aluminum parts.

Gearbox, steering rack, diff, spool, damper, battery holder and a few more..

Gearbox, steering rack, diff, spool, damper, battery holder and a few more..

6. Dampers.

Not much to describe here. A steering rack that sits on three ball

bearings the outer one being adjustable thus you can achieve better balance between

minimal slop and friction. Also the whole steering assembly has adjustable position on the chassis for better allignment with the ackerman positon on the steering blocks and the servo.

8. Gearbox

The gearbox houses the gears and in the front the steering

rack as well. The gear shafts are supported by

double bearings in front and a single bearing at the rear. The rear will be

further supported when the spur gear holder is installed. The fit is again

incredibly precise with absolutely no movement at all of the bevel gear once

installed.

9. Gear diff

The gear diff is a work of art. Aluminum art that is. The housing is

paper thin, thus minimizing the weight and the outdrives are made of hard

steel, the color of which resembles that of our familiar spring steel. The internals

are made by Spec-R and as I had in my possession the optional carbon gears I installed

these. What is impressive is that the

small carbon gears that I used from the Spec-R optional kit require some

resizing in order to fit in the tight space inside the gearbox and the standard

gears that are included in the kit have already been resized to the required

dimensions for a perfect fit.

10. Upper camber links and turnbuckles

A testament to the high quality of this kit is that such

simple parts can look so nice. The turnbuckles are very lightweight aluminum

and have a beautiful gun-metal color. The plastic ball ends are of high quality

material that fits perfectly to the thread of the turnbuckle. They are not too

tight nor too loose.

I initially installed the gearboxes without their covers in order to show how the drivetrain looks installed.

11. Middle shaft holder to eliminate any vibrations on the main centrla shaft that connects the front to the rear gearbox. Very

smart!

12. Spur gear installation. Another very smart design which

results in super quick spur gear changes. The spur gear holder has two small

pins which feet snugly in the holes of the spur gear and then the whole

assembly is secured by a very light nut. It takes no more than 2 minutes to

make a spur gear change.

13. Front bumper, body posts, battery holder

The front end is similar to most current designs with a foam

bumper that houses the body posts. The rear end on the other hand has some very

unique body post holders which also have the option to hold horizontal body

posts, a common feature in the cars of most top pro drivers who want to avoid

the body being tucked in when hit from behind. Super nice finish again, with

dark gun metal anodizing and a small M2.5 screw to secure the body post.

14. A series of photos from the assembled chassis.

15. Final thoughts.

This

is by far the highest quality kit that I’ve ever assembled, and I have

assembled quite a few ‘high end’ kits, from Xray to Tamiya, HB, Yokomo, CRC and

a few more. The most impressive thing is of course the innovative design which

would have been a complete failure if the quality did not match the demands of

this design. Oleg and his team have succeeded perfectly in supplying a kit of

the highest standards.

This kit is for the expert only and requires good knowledge of assembling technics. It does not require any hand fitting or corrective action, it is just that some parts are so tiny and require finesse to install that the inexperience hobbyist may find it very hard to succeed and may damage the kit before it is even used on the track.

This kit is for the expert only and requires good knowledge of assembling technics. It does not require any hand fitting or corrective action, it is just that some parts are so tiny and require finesse to install that the inexperience hobbyist may find it very hard to succeed and may damage the kit before it is even used on the track.

Positive

*--- Design and innovation

*--- Quality

*--- Fit and finish

*--- Looks, visual appeal

*--- Unlimited tuning options

*--- Optional & additonal parts included for:

a) drive train orientation

b) upper link position (long or short)

b) upper link position (long or short)

c) parts that may be lost or damaged during assembly

*--- Manual presentation, graph on suspesnion settings and gear ratios

*--- Description of all possible electronic installation orientation / layout

*--- Support from the designer himself on rctech and company website

Negative:

*--- Packing not as nice, box quite simple.

*--- Bags inside are not labeled / numbered.

*--- Packing not as nice, box quite simple.

*--- Bags inside are not labeled / numbered.

*--- Manual could have a bit more detail on some assembly stages

*--- I received the kit for presentation purposes only but now I want to keep it and not return it so I'm in trouble!

Expect more updates really soon with electronics

installation (this will be epic) and should the weather allow, first test

impressions.

Labels:

1/10 scale,

A700,

Awesomatix,

EFRA,

electric,

IFMAR,

inovation,

ISTC,

JMRCA,

quality,

r/c car,

russian,

touring car

Subscribe to:

Posts (Atom)